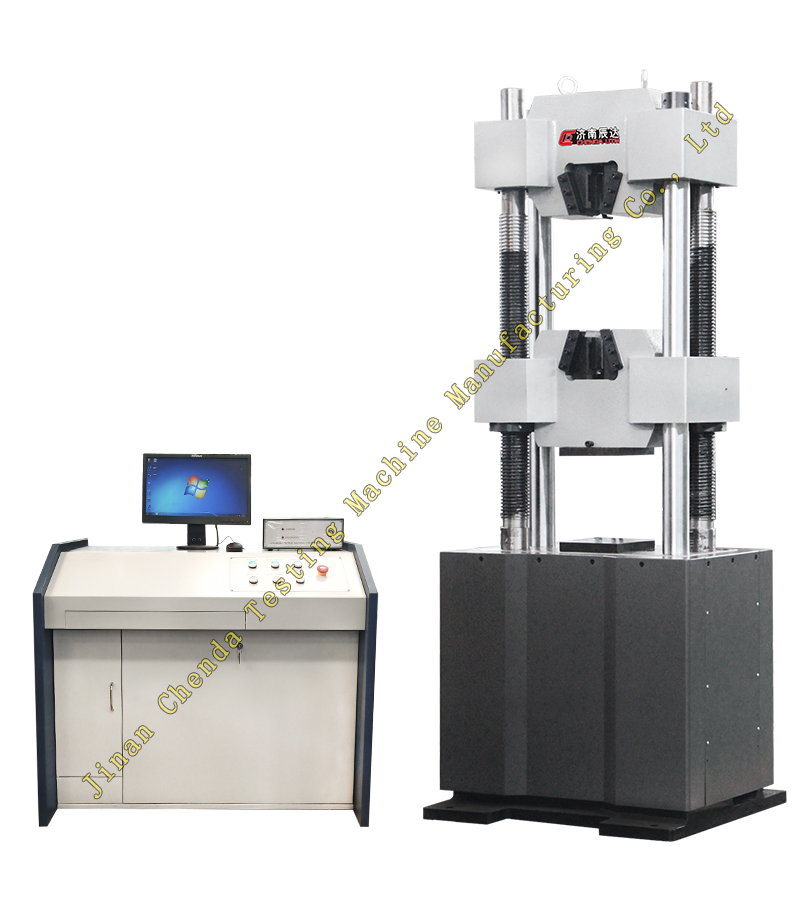

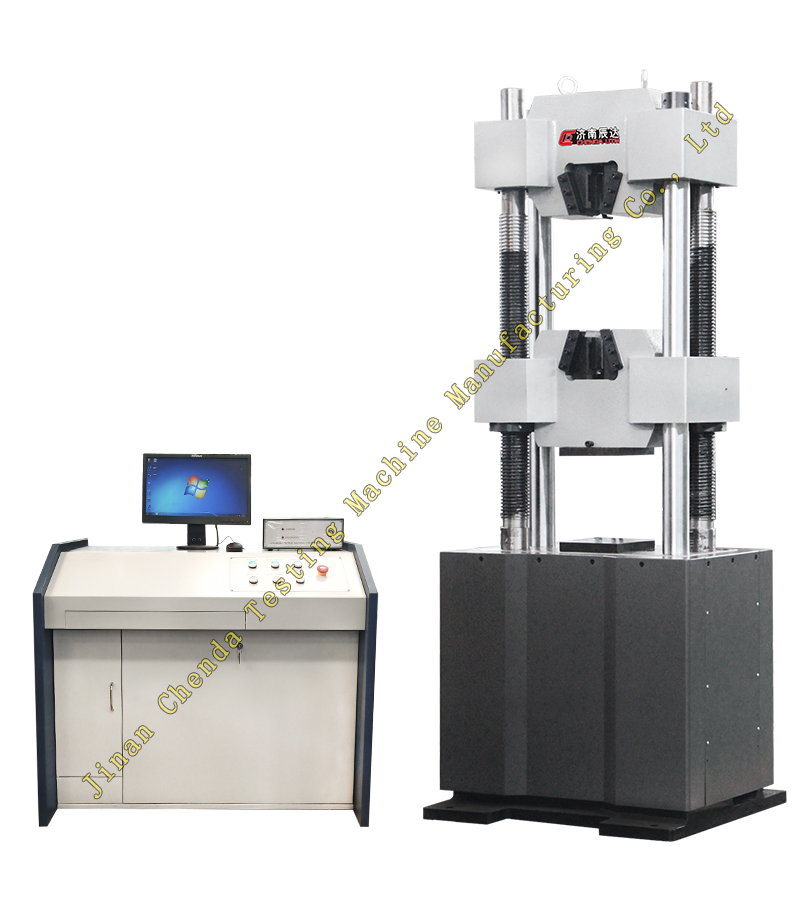

The universal testing machine is a core testing equipment in the power industry that ensures material quality, equipment safety, and stable system operation. It covers the entire process of power generation, transmission, transformation, and distribution, and accurately tests the mechanical properties (tension, compression, bending, shearing, peeling, etc.) of metal, non-metal, and composite materials to build a strong safety line for power engineering construction and equipment operation and maintenance. Its specific functions are as follows:

Firstly, focus on the detection of power core equipment components. The key components such as generator rotor shaft, transformer winding copper bar, circuit breaker contact spring, and switchgear busbar need to withstand long-term mechanical stress, temperature fluctuations, and electromagnetic vibrations. The universal testing machine tests their tensile strength, yield strength, fatigue limit, and other indicators to verify whether the materials meet the design requirements, prevent faults such as fracture and deformation during operation, and avoid major accidents such as generator shutdown and transformer short circuit.

Secondly, safeguard the safety of transmission lines. The steel core aluminum stranded wire, insulator fittings, tower angle steel, wire ropes and other materials of overhead transmission lines need to withstand wind, ice and snow loads, and long-term tensile stress. The testing machine can detect their tensile fracture strength, bending deflection, and shear resistance to ensure that the wires do not break, fittings do not fall off, and towers do not collapse, ensuring the stable operation of cross regional transmission channels; Simultaneously conduct tensile and tear tests on the cable sheath and insulation layer to prevent the risk of leakage and short circuit caused by cable damage.

Thirdly, support the construction of power station infrastructure and the acceptance of auxiliary materials. Concrete load-bearing components, steel structure plant supports, and cooling tower tube materials for thermal power plants, nuclear power plants, and hydropower stations need to be verified for structural strength through compressive, flexural, and tensile tests; The mechanical performance testing of steel for cable trays and grounding devices also relies on universal testing machines to ensure that power station infrastructure projects meet seismic and heavy load resistance standards, avoiding building collapse or equipment overturning.

In addition, it helps with quality control and fault tracing. When raw materials are stored, sampling and testing of steel, aluminum, and insulation materials are carried out to prevent inferior materials from entering the production process; After equipment failure, mechanical performance analysis is conducted on the failed components to identify material defects and processing technology issues, providing data support for equipment modification and process optimization. At the same time, the inspection report is also a necessary basis for power equipment to pass industry certification and meet national standards.

In short, the universal testing machine runs through the entire process of the power industry from raw material acceptance, equipment manufacturing to engineering construction, and is a key tool for preventing safety hazards and ensuring the reliable operation of the power system.