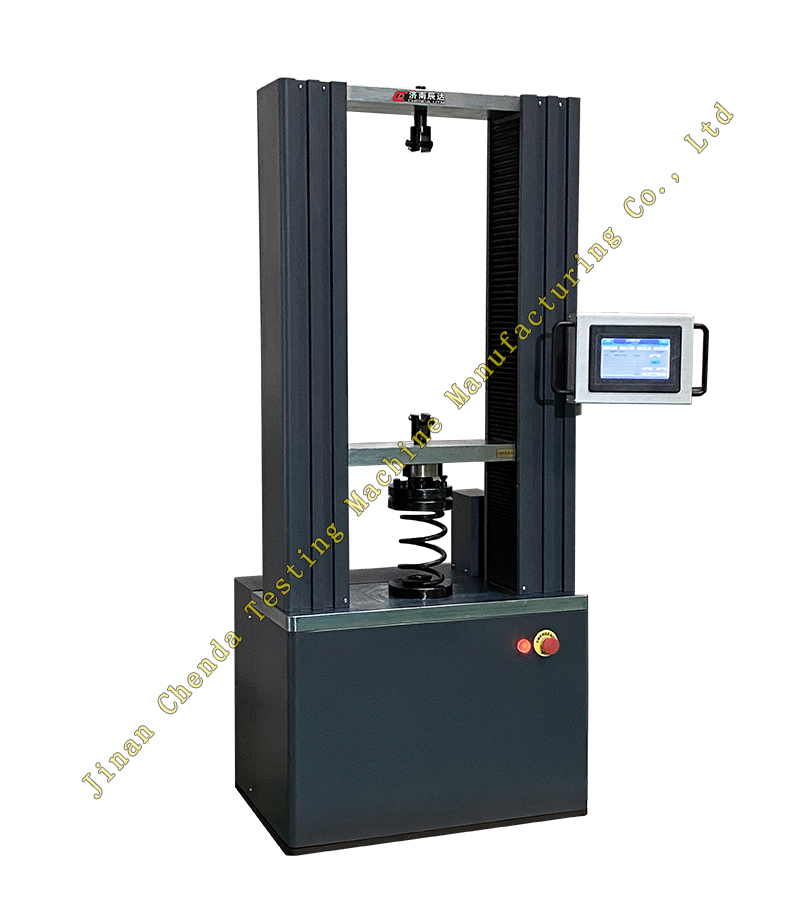

The spring testing machine tests the core performance of springs

The spring testing machine is a specialized equipment for spring production and quality inspection, capable of comprehensively testing the static and dynamic properties of springs. It provides quantitative data support for product reliability, covering the entire process of spring design, production, and acceptance. The core testing performance encompasses four aspects.

Firstly, stiffness and elasticity testing. This is a basic performance indicator for springs. The testing machine applies gradual loads to the spring, accurately measures the relationship between load and deformation, calculates the spring stiffness coefficient (spring constant), and determines whether the spring conforms to the designed elastic deformation pattern. At the same time, it tests the deflection and elastic limit of the spring, verifies whether the deformation of the spring under rated load meets the standard, ensures that there is no permanent plastic deformation after unloading, and avoids problems such as equipment operation stagnation and shock absorption failure caused by stiffness deviation.

Secondly, strength and load-bearing performance testing. For different types of products such as compression springs, tension springs, and torsion springs, the testing machine can conduct ultimate load testing to determine the maximum tensile/compressive/torsional strength of the spring and clarify the safe load-bearing boundary of the spring. It can also detect yield strength and failure strength, locate the critical point of plastic deformation of the spring and the load value at fracture failure, providing data basis for load matching of the spring in engineering applications and preventing spring fracture and failure caused by overload.

Thirdly, fatigue and durability testing. Conduct cyclic loading tests by simulating the actual working conditions of springs, record the performance changes of springs under tens of thousands or even millions of alternating loads, measure the fatigue life and durability limit, and assess the fatigue resistance of springs after long-term use. Through durability tests, early failure issues caused by material defects or improper heat treatment processes can also be identified, making it suitable for quality inspection of high-frequency stressed products such as automotive suspension springs and home appliance switch springs.

Fourthly, special performance testing. For springs under specific working conditions, the testing machine can detect torsional performance (torsional angle, peak torque), stress relaxation performance (stress attenuation under long-term load or high temperature environment), and impact resistance performance (deformation and recovery ability under instantaneous impact load), meeting the special performance requirements of springs in high-end fields such as aerospace and engineering machinery.

In summary, the spring testing machine provides a scientific basis for quality control of spring products through multi-dimensional performance testing, and is a key tool for ensuring stable operation of downstream equipment.